Are you tired of skyrocketing energy bills and stuffy indoor air? Imagine a heating system that warms your home and ensures fresh, clean air circulates throughout. Enter the HRV heating system—a game-changer in modern ventilation technology. This innovative approach to maintaining comfortable indoor environments is gaining traction among homeowners looking for energy efficiency and improved air quality.

Whether you’re considering installation or simply curious about how it works, you’re in the right place. Let’s uncover the secrets behind heat recovery units and explore why they might be the solution you’ve been searching for.

How Does a Heat Recovery Unit Work?

A heat recovery unit transfers warmth from outgoing air to incoming fresh air, enhancing energy efficiency in heating systems. When warm, stale indoor air is expelled, it moves through a heat exchanger. The heat from this air warms the cooler outdoor air entering your home.

As a result, you maintain comfortable indoor temperatures without straining your heating system unnecessarily. The exchanged heat minimizes energy loss while providing clean ventilation. Another key feature of these units is moisture removal. They help balance humidity levels indoors, ensuring a healthier environment.

This method preserves energy and supports consistent airflow throughout your living spaces. It’s an intelligent way to harness existing thermal resources for improved comfort and reduced costs.

Types of Heat Recovery Unit

When exploring Heat Recovery Ventilation systems, it’s essential to understand the various types of heat recovery units. Each type offers unique features tailored to specific needs.

1. Plate Heat Exchangers

Plate heat exchangers are the most common type of heat recovery unit. They consist of numerous thin plates with alternating exhaust and fresh air flow channels. The plates are designed to transfer heat between the two airstreams without mixing them, thereby recovering heat from exhaust air and preheating incoming fresh air.

2. Rotary Heat Exchangers

Rotary heat exchangers use a rotating wheel made of a material with high thermal conductivity, such as aluminium or polymeric substances, to transfer heat between the two airstreams. As the wheel rotates, it alternately exposes the warm exhaust air and cold incoming fresh air to its surface, allowing for efficient heat exchange.

3. Run-Around Coils

Run-around coils use separate coils in each airstream connected by a circulating liquid, typically water or refrigerant. The heated or cooled liquid transfers energy between the two airstreams without allowing them to mix, making it an ideal choice for environments where cross-contamination is a concern.

4. Heat Pipes

Heat pipes are innovative heat recovery units that use sealed tubes filled with a working fluid such as refrigerant or water to transfer heat between exhaust and fresh air streams. As the exhaust air heats the liquid, it vaporizes and transfers heat to the cool fresh air stream, which condenses and releases the heat. The condensed liquid then flows back to the exhaust airstream, completing the cycle. Heat pipes are compact and efficient, ideal for smaller spaces or retrofit applications.

Benefits of Using a Heat Recovery Unit

A Heat Recovery Ventilation system offers homeowners many advantages. First and foremost, it enhances indoor air quality by exchanging stale air with fresh outdoor air. This process reduces allergens and pollutants, creating a healthier living environment.

Additionally, heat recovery units are energy-efficient. They capture the heat from outgoing air and warm incoming fresh air, reducing your heating bill significantly during colder months.

Moreover, these systems maintain consistent temperature levels throughout your home. No more chilly drafts or overheated rooms—just comfortable spaces year-round. Another benefit is their ability to control humidity levels. By managing moisture in the air, they prevent mould growth and protect building materials from damage.

An HRV system operates quietly in the background while making all these improvements. You’ll enjoy comfort without disruptive noise interfering with daily life or relaxation time.

Factors to Consider Before Installing an HRV Ventilation System

Before installing an HRV ventilation system, assessing your home’s layout and size is essential. The effectiveness of the system depends on proper airflow distribution throughout the space.

Some other benefits include:

1. Improved Energy Efficiency: HRV systems are designed to recover heat from the outgoing air and transfer it to the incoming air, reducing the energy needed to heat your home. This can lead to significant cost savings on your heating bill.

2. Increased Comfort: An HRV system continuously brings in fresh air, helping regulate the humidity levels in your home and making it more comfortable year-round.

3. Reduced Condensation & Mould: HRV systems help prevent condensation and mould growth by removing excess moisture from the air.

4. Quieter Operation: Unlike traditional ventilation systems that require windows or doors to be left open for fresh air, an HRV system operates quietly and efficiently without any drafts or noise.

Maintenance and Cost of Heat Recovery Unit

Maintaining a Heat Recovery Ventilation system is essential for optimal performance. Regular checks ensure efficient operation and prolong the unit’s lifespan. Filter replacement is a key maintenance task. Clogged filters can hinder airflow, significantly reducing efficiency. It’s advisable to inspect these every few months.

Cleaning the heat exchange core is equally important. Dust or debris buildup here can impact heat transfer capabilities. A thorough clean annually should suffice. Regarding cost, the initial installation of an HRV system can be higher than that of traditional systems. However, energy savings over time often offset this expense.

When budgeting for your HRV unit’s upkeep, consider potential repairs as well. While generally durable, components may need replacing after years of use. Investing in proper maintenance pays off with increased efficiency and lower energy bills.

Installation and Maintenance of a Heat Recovery Unit

Installing a Heat Recovery Ventilation system requires careful planning and professional expertise. It’s essential to assess your home’s design and airflow patterns before installation. This ensures optimal performance.

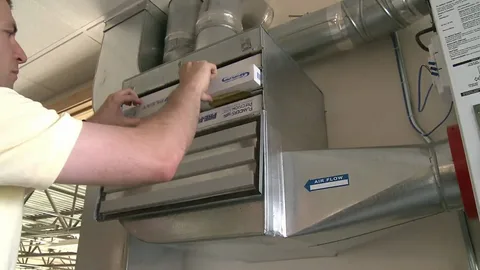

The installation typically involves:

- Placing the heat recovery unit in a central location.

- Connecting ductwork throughout the house.

- Ensuring establishing proper ventilation points.

A qualified technician can effectively navigate local building codes and safety regulations.

Once installed, maintenance is key to sustaining efficiency. Regular filter checks should be part of your routine—cleaning or replacing filters every few months keeps dust and allergens at bay.

Remember that even minor neglect in maintenance can lead to significant drops in performance over time; staying proactive benefits both comfort and energy savings.

Comparison with Traditional Heating Systems

Several key differences emerge when comparing an Heat Recovery Ventilation system to a traditional heating system. Traditional systems often rely solely on fossil fuels or electricity for heat, which can lead to higher energy bills and increased environmental impact.

In contrast, HRV systems utilize a heat recovery process that captures waste heat from indoor air and uses it to warm incoming fresh air.

Another aspect is the constant airflow provided by HRV systems. While conventional heaters might leave spaces stagnant, HRVs ensure consistent fresh air circulation throughout your home.

Maintenance requirements also vary significantly. Traditional systems may demand frequent servicing due to their complexity and reliance on combustion processes, whereas HRVs typically require less attention once correctly installed.

Common Misconceptions About Heat Recovery Unit

Many believe a heat recovery unit is only suitable for new builds. This isn’t true; retrofitting an Heat Recovery Ventilation system into existing homes can be effective and enhance energy efficiency.

Another misconception is that these systems are noisy. Modern units operate quietly and often have adjustable settings to suit individual preferences. Some think installation requires extensive ductwork.

Additionally, many assume they will drive up energy costs. On the contrary, an HRV system typically reduces overall heating expenses by recapturing heat from stale air.

Some homeowners worry about maintenance being too demanding. In truth, regular filter changes and occasional inspections make upkeep straightforward and manageable for most people.

Conclusion

The HRV heating system is an innovative solution for modern homes. It enhances comfort and promotes energy efficiency. Understanding how these systems function can empower homeowners to make informed choices. Proper installation and maintenance of an HRV unit can significantly improve indoor air quality while reducing energy costs. As technology evolves, more people discover the numerous benefits of investing in HRV ventilation systems. They cater to a growing need for sustainable living without compromising on comfort.

FAQs

What is an HRV heating system?

An HRV heating system, or Heat Recovery Ventilation system, is designed to exchange stale indoor air with fresh outdoor air while recovering most of the heat from the outgoing air. This ensures that your home remains comfortable without incurring high energy costs.

How often should I maintain my HRV ventilation system?

Regular maintenance is essential for optimal performance. It’s recommended that filters be cleaned or replaced every three months and that professional inspection be scheduled at least once a year.

Can an HRV unit work in all climates?

Yes, an HRV unit can be beneficial in various climates. It efficiently manages humidity levels while ensuring proper ventilation, making it suitable for cold and warm areas, although its efficiency may differ based on local weather conditions.