In industrial automation and material handling, vacuum cups are essential tools for lifting, holding, and moving objects. Among the various types, the flat vacuum cup is one of the most commonly used due to its versatility and effectiveness in handling a wide range of materials.

How Do Flat Vacuum Cups Work?

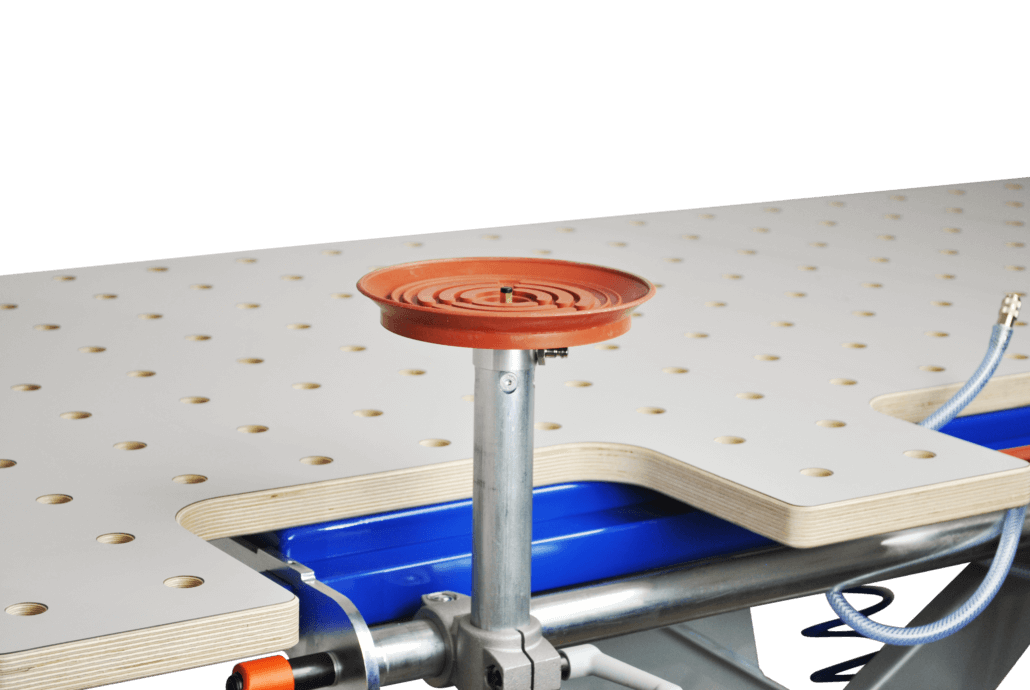

Flat vacuum cups operate by creating a vacuum between the cup and the surface of the object being handled. When the cup is pressed against the object, the air inside the cup is expelled, creating a low-pressure area (vacuum). This vacuum generates a strong suction force, allowing the cup to hold onto the object securely.

Characteristics of Flat Vacuum Cups

Flat vacuum cups are characterized by their flat, smooth surface. This design provides several advantages:

- Strong Grip on Flat Surfaces: The flat design allows these cups to maintain a strong grip on smooth, flat surfaces like glass, metal, or plastic sheets.

- Even Distribution of Force: The flat surface ensures an even distribution of the suction force across the contact area, reducing the risk of damaging delicate materials.

- Versatility: Flat vacuum cups can be used with a variety of materials, making them suitable for applications across different industries, such as automotive, electronics, and packaging.

Applications of Flat Vacuum Cups

Flat vacuum cups are used in numerous applications where precision and stability are crucial:

- Automotive Industry: In car manufacturing, flat vacuum cups are used to handle body panels, glass windows, and other flat components.

- Packaging Industry: These cups are ideal for picking and placing items in packaging processes, ensuring the products are handled gently and efficiently.

- Electronics Manufacturing: Flat vacuum cups are employed to handle delicate components like circuit boards and displays without causing damage.

Advantages of Using Flat Vacuum Cups

Flat vacuum cups offer several benefits that make them a preferred choice in many industries:

- High Holding Force: The flat design maximizes contact with the surface, providing a strong and reliable grip.

- Reduced Risk of Slippage: The even suction distribution minimizes the chances of slippage, ensuring secure handling of objects.

- Minimal Marking: Flat vacuum cups are less likely to leave marks or imprints on the surface of the materials they handle, making them ideal for delicate and aesthetic-sensitive applications.

Choosing the Right Flat Vacuum Cup

When selecting a flat vacuum cup, consider factors such as the material of the cup, the surface of the object being handled, and the environmental conditions. Different materials like silicone, nitrile, or polyurethane offer varying levels of durability, flexibility, and resistance to chemicals or temperature extremes.

Conclusion

Flat vacuum cups are indispensable tools in various industrial applications, providing a reliable, efficient, and safe means of handling flat and smooth surfaces. Their versatility and effectiveness make them a valuable component in any material handling system, ensuring that products are moved with precision and care.

By understanding the key features and advantages of flat vacuum cups, you can make informed decisions about their use in your specific applications, optimizing your processes and enhancing overall productivity.