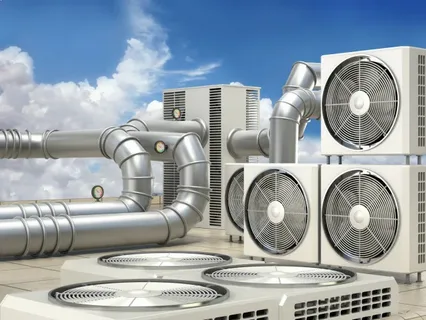

Energy recovery ventilators (ERVs) are crucial in maintaining indoor air quality and conserving energy. By exchanging stale indoor air with fresh outdoor air, ERVs help create a healthier living environment. These devices transfer heat and moisture between incoming and outgoing air streams, making them highly energy-efficient. ERVs’ Essential components include air distribution ductwork, fans for air movement, and filters for removing particulates. Proper selection and installation of an ERV can significantly enhance indoor air quality and comfort.

Varieties of Ventilation Systems

Different types of ventilation systems cater to various needs and preferences:

Natural ventilation uses wind and thermal buoyancy to circulate air through open windows, doors, or vents. This method is energy-efficient but relies on outdoor conditions.

Mechanical ventilation systems use fans and ductwork to circulate air actively. They provide better control over air quality and are effective regardless of outdoor conditions.

Hybrid ventilation systems combine natural and mechanical methods to enhance energy efficiency and indoor comfort. They automatically switch between modes based on environmental conditions.

Significance of Ventilation Systems for Indoor Air Quality

Ventilation systems are vital in ensuring indoor air remains fresh and healthy. By consistently circulating air, they help reduce the concentration of indoor pollutants such as carbon dioxide, volatile organic compounds (VOCs), and allergens. Efficient ventilation contributes to a healthier living environment, decreasing the risk of respiratory issues and improving overall comfort. Properly installed systems also help manage humidity levels, preventing mould growth and structural damage. High-quality ventilation enhances occupants’ well-being and productivity in residential and commercial spaces.

Components of an Energy Recovery Ventilator

Key components of energy recovery ventilators include ductwork, fans, and filters. Ductwork facilitates air transport between different zones within a building and the ERV unit. Fans are essential for driving air movement within the system, and their correct sizing and maintenance are crucial for optimal performance. Filters play a pivotal role in eliminating particulates and pollutants from the air. Regular maintenance and timely replacement of filters ensure the system functions effectively and maintains high air quality. Properly functioning components contribute to energy recovery ventilators’ overall efficiency and effectiveness.

Functioning of Energy Recovery Ventilators

Energy recovery ventilators function through the principles of heat and moisture exchange. They transfer thermal energy and humidity between incoming fresh air and outgoing stale air, ensuring energy efficiency while maintaining indoor comfort. The core component, known as the heat exchanger, facilitates this transfer by allowing the two air streams to pass close to each other without mixing. Depending on the season, this process enables the incoming air to be pre-conditioned, either warmed or cooled. As a result, energy consumption for heating and cooling is reduced, contributing to overall energy savings. Effective operation requires balanced airflow and regular maintenance to ensure optimal performance.

Selecting the Appropriate Energy Recovery Ventilator

When selecting an energy recovery ventilator, consider factors such as the size of the space, specific indoor air quality requirements, and budget constraints. It’s essential to choose a model with the appropriate capacity to handle the air volume of the area. Evaluate features such as energy efficiency, noise levels, and ease of maintenance. Additionally, check for compatibility with existing heating, ventilation, and air conditioning (HVAC) systems. Consulting a professional for a detailed assessment can help make an informed decision, ensuring the selected ERV meets the space’s specific needs while providing optimal performance.

Installing a Mechanical Ventilation System

Thorough preparation is crucial when installing a mechanical ventilation system. Start by evaluating the building’s layout and determining its air quality needs. Plan the ductwork layout meticulously, ensuring efficient airflow throughout the space. Install the ERV unit appropriately, typically in a utility room or attic. Carefully connect the ductwork to the unit, securing all joints and connections to prevent air leaks. Ensure that electrical connections are safely made and comply with local regulations. After installation, thoroughly test the system to confirm it operates correctly and efficiently. Address any issues immediately to ensure optimal performance and energy efficiency.

Maintaining a Mechanical Ventilation System

Regular maintenance is essential for the longevity and efficiency of a mechanical ventilation system. Establish a schedule to inspect ductwork and components for any signs of wear or damage. Clean and replace filters according to the manufacturer’s guidelines to maintain optimal airflow. Ensure that fans and motors operate correctly, lubricating moving parts as needed. Periodically check for any obstructions or blockages within the ductwork that could impede performance. If the system includes sensors or controls, verify their functionality and recalibrate them if necessary. Always follow safety protocols and consult the user manual or a professional technician for detailed maintenance procedures.

Common Problems and Troubleshooting of Mechanical Ventilation Systems

Common issues with mechanical ventilation systems include decreased airflow, unusual noises, and increased energy consumption. Troubleshooting these problems involves inspecting ductwork for blockages or leaks, ensuring filters are clean and properly installed, and checking fans and motors for signs of wear or malfunction. Additionally, verify that electrical connections are secure and meet local standards. Recalibrate sensors or controls to ensure accurate operation if they are part of the system. Address any identified issues promptly to maintain system efficiency and performance.

Advantages of Routine Maintenance of Mechanical Ventilation Systems

Regular maintenance of mechanical ventilation systems ensures optimal functionality and efficiency. Addressing minor issues promptly can prevent costly repairs and extend the system’s lifespan. Keeping filters clean and replacing them as needed maintains airflow and air quality. Lubricating moving parts and checking electrical connections help the system operate smoothly. Routine inspections also identify potential blockages or obstructions in the ductwork, ensuring uninterrupted performance. Adhering to a maintenance schedule can result in lower energy consumption and reduced utility bills. Ensuring all components are in good working order enhances overall reliability and performance, providing a healthier indoor environment.

Energy Efficiency in Mechanical Ventilation Systems

Enhancing energy efficiency in mechanical ventilation systems involves utilising energy-efficient fans and motors, which consume less electricity while maintaining performance. Integrating energy-saving technologies such as variable speed controls can adjust airflow based on demand, reducing unnecessary energy use. Proper insulation of ductwork minimises heat loss and improves overall system efficiency. Additionally, regular system maintenance ensures all components function optimally, preventing energy wastage. Upgrading to high-efficiency filters can also improve airflow and reduce energy consumption. Implementing these strategies can lead to significant energy savings and lower operating costs.

Regulations and Standards for Mechanical Ventilation Systems

In the UK, compliance with ventilation standards is mandatory. The Building Regulations, particularly Part F, set the minimum ventilation requirements for different types of buildings to ensure adequate air quality and energy efficiency. Standards from organisations such as the British Standards Institution (BSI) provide detailed guidance on the design, installation, and maintenance of ventilation systems. Adhering to these regulations and standards is essential for achieving certification and ensuring the system operates effectively and safely. Regular inspections and updates may be required to stay compliant with evolving standards. Consulting with certified professionals can aid in understanding and implementing these requirements correctly.

Innovations in Mechanical Ventilation System Technology

Recent advancements in mechanical ventilation technology include developing intelligent systems capable of optimising airflow based on real-time data. These smart-systems use sensors to monitor indoor air quality, automatically adjusting ventilation rates to maintain optimal conditions. Innovations also encompass integration with home automation systems, allowing remote control and tracking through mobile apps. Enhanced energy recovery technologies have emerged, offering higher efficiency and better performance, particularly in extreme climates. Additionally, introducing advanced filtration systems improves air purification, capturing smaller particulates and pollutants more effectively. These technological advancements contribute to more efficient, responsive, and user-friendly ventilation solutions, catering to modern indoor air quality and energy conservation requirements.

Conclusion

A well-functioning ventilation system is essential for creating a comfortable and healthy indoor environment. By continually circulating fresh air and removing pollutants, these systems help to mitigate respiratory issues and enhance overall well-being. Energy recovery ventilators offer an efficient solution by improving air quality and conserving energy. Different systems cater to specific needs, whether in residential or commercial settings. Proper selection, installation, and regular maintenance ensure optimal performance and energy efficiency. With technological advancements, modern ventilation systems offer innovative features and higher efficiency, making maintaining indoor air quality easier.

Frequently Asked Questions

Why is a ventilation system crucial for indoor air quality?

Ventilation systems improve indoor air quality by removing pollutants, excess moisture, and stale air while introducing fresh outdoor air. This helps create a healthier and more comfortable living or working environment.

How does poor ventilation affect health?

Inadequate ventilation can lead to the buildup of harmful pollutants, allergens, and carbon dioxide, potentially causing respiratory issues, fatigue, headaches, and other health problems, particularly for those with allergies or asthma.

What types of ventilation systems are available for homes and businesses?

Common types include natural ventilation (e.g., windows and vents), mechanical ventilation (e.g., exhaust fans and HVAC systems), and hybrid systems, which combine natural and mechanical methods for optimal performance.

How do ventilation systems contribute to energy efficiency?

Modern ventilation systems, like heat recovery ventilators (HRVs), reduce energy loss by capturing heat from outgoing air to warm incoming fresh air, lowering heating and cooling costs.

What maintenance does a ventilation system require?

Regular maintenance includes cleaning or replacing filters, inspecting ducts for blockages or leaks, and servicing fans and motors to ensure the system operates efficiently and effectively.

Can a ventilation system eliminate all indoor air pollutants?

While ventilation systems significantly reduce indoor air pollutants, they may not destroy them. Combining a ventilation system with air purifiers or dehumidifiers can enhance air quality, especially in high-pollution or humid areas.