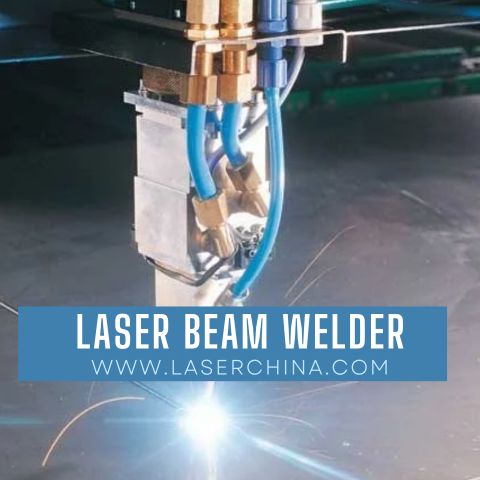

In the world of manufacturing, precision and efficiency are paramount. The LASERCHINA Laser Beam Welding Machine stands as a cutting-edge solution, delivering unmatched accuracy and performance. Whether you’re in the automotive, aerospace, or electronics industry, this advanced welding machine is designed to meet the most stringent demands. Let’s explore the features and benefits that make the LASERCHINA Laser Beam Welding Machine an essential tool for modern manufacturing.

Why Choose LASERCHINA Laser Beam Welding Machine?

Laser beam welding has revolutionized the way we think about joining materials. Unlike traditional welding methods, which rely on heat generated by electric currents or flames, laser beam welding uses concentrated light to melt and fuse materials together. The LASERCHINA Laser Beam Welding Machine harnesses this technology to provide superior weld quality, with minimal distortion and high-speed processing.

Unmatched Precision

One of the standout features of the LASERCHINA Laser Beam Welding Machine is its precision. The machine’s laser beam can be focused to an extremely small point, allowing for tight control over the welding process. This precision ensures that each weld is consistent and strong, even in complex and delicate assemblies. For industries where micro-welding is required, such as in electronics or medical device manufacturing, this level of accuracy is invaluable.

High-Speed Performance

In today’s fast-paced manufacturing environments, speed is just as important as precision. The LASERCHINA Laser Beam Welding Machine delivers on both fronts. With its high-speed laser technology, this machine can complete welds faster than traditional methods, without sacrificing quality. This increased efficiency leads to shorter production times and lower operational costs, making it an ideal choice for high-volume production lines.

Versatility Across Materials

The LASERCHINA Laser Beam Welding Machine is designed to handle a wide variety of materials, from traditional metals like steel and aluminum to more exotic alloys and composites. This versatility makes it an indispensable tool for manufacturers who need to work with diverse materials. Whether you’re welding thin sheets or thick plates, this machine provides consistent, high-quality welds.

Minimal Distortion and Post-Processing

Traditional welding methods often cause significant heat distortion, requiring extensive post-processing to correct. The LASERCHINA Laser Beam Welding Machine minimizes this issue by delivering highly concentrated energy directly to the weld joint. The result is minimal thermal distortion, reducing the need for time-consuming and costly post-weld treatments. This advantage not only improves production efficiency but also enhances the overall quality of the final product.

Ease of Integration

The LASERCHINA Laser Beam Welding Machine is designed with user-friendliness in mind. Its intuitive interface and flexible configuration options make it easy to integrate into existing production lines. Whether you’re upgrading from an older system or setting up a new line, the transition is seamless, with minimal downtime. Additionally, LASERCHINA offers comprehensive training and support to ensure that your team can fully leverage the machine’s capabilities.

Environmental Benefits

In an era where sustainability is increasingly important, the LASERCHINA Laser Beam Welding Machine offers significant environmental benefits. The machine’s energy-efficient laser technology reduces power consumption compared to traditional welding methods. Moreover, the precision of laser welding reduces material waste, contributing to a more sustainable manufacturing process overall.

Conclusion

The LASERCHINA Laser Beam Welding Machine is more than just a tool—it’s an investment in quality, efficiency, and innovation. With its unmatched precision, high-speed performance, and versatility across materials, this machine is set to redefine the standards of modern manufacturing. By choosing LASERCHINA, you’re not only enhancing your production capabilities but also positioning your business at the forefront of technological advancement.