Heat exchanger-fans are crucial in efficiently transferring heat between two fluids. These devices are used in various industrial processes and HVAC systems to maintain optimal temperatures. As the name suggests, heat exchanger fans are responsible for moving air or other gases over the heat exchange surfaces to facilitate thermal energy transfer. In this blog article, they will delve into the workings of heat exchanger-fans s and explore their importance in achieving efficient heat transfer.

Understanding the Heat Exchanger-Fans

Heat exchanger-fans s are critical components in thermal management systems. They facilitate the transfer of heat between two fluids without allowing them to mix, which is essential for maintaining efficient operational temperatures across various industries. These fans work by enhancing airflow over the surface area of heat exchangers, promoting improved heat dissipation or absorption. By increasing contact with ambient air, they optimize the performance of cooling and heating processes.

The design and efficiency of these fans directly influence how well a system operates. Properly selected fans can save energy while ensuring equipment runs within safe temperature ranges. Understanding their mechanics, which emphasizes functionality and reliability, helps businesses achieve better performance outcomes. These fans not only contribute to effective thermal regulation but also play a role in extending equipment lifespan, making them indispensable in many industrial applications.

Function and Importance of Heat Transfer in Industrial Processes

Heat transfer plays a crucial role in industrial processes. It affects efficiency, safety, and product quality. Without effective heat management, systems can overheat or operate inefficiently. Different industries rely on heat exchange for various applications. In manufacturing, it helps regulate temperature during chemical reactions. This ensures optimal conditions for production and reduces waste. Efficient heat transfer is vital for converting fuels into usable power in energy generation. Thermal plants depend on robust systems to maintain performance while minimizing emissions.

Moreover, proper heat exchange contributes to equipment longevity. When temperatures are managed effectively, wear and tear decreases significantly. Neglecting this aspect can lead to catastrophic failures or costly downtimes. Prioritizing reliable heat transfer mechanisms is key to maintaining operational integrity across diverse sectors.

Benefits of Using High-Quality Heat Exchanger-Fans

High-quality heat exchanger-fans s ensure efficient heat transfer in various systems and improve performance and energy efficiency.

Improved Energy Efficiency

Using high-quality heat exchanger-fans s ensures better airflow, reduces energy consumption and helps maintain optimal temperatures with less power.

Enhanced Performance

With optimized design and high durability, these fans contribute to maintaining consistent performance in heat-exchange systems, improving overall system efficiency.

Longer Lifespan

Durable and reliable, high-quality heat exchanger-fans s are designed to last longer, reducing the frequency of replacements and lowering long-term maintenance costs.

Consistent Temperature Control

These fans offer precise control over temperature regulation, allowing systems to function efficiently without overheating or underperforming, ensuring stability.

Noise Reduction

High-quality fans are designed to operate quietly, reducing operational noise and creating a more comfortable and efficient working environment.

Reduced Maintenance Costs

Since quality fans are less prone to failure and wear, they help reduce maintenance requirements, resulting in lower operational costs and improved system longevity.

Types of Heat Exchanger-Fans S

Heat exchanger-fans s come in various types, each serving distinct purposes within industrial applications. Axial fans are the most common, utilizing a propeller-like design to move air parallel to the fan shaft. They excel in situations requiring high airflow at low pressure. Centrifugal fans, on the other hand, draw air into the centre and expel it at right angles. Their robust construction makes them suitable for applications demanding higher pressures, such as HVAC systems or large-scale cooling operations.

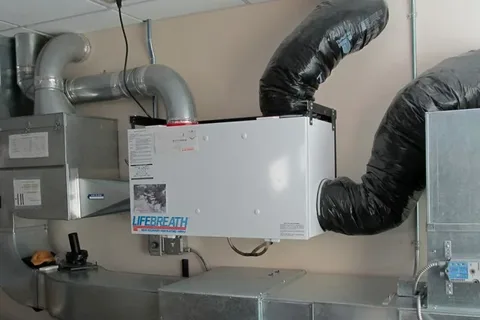

Mixed-flow fans combine features of both axial and centrifugal designs. This versatility allows them to handle moderate pressures while maintaining relatively high airflow rates. Additionally, specialized heat recovery ventilators incorporate heat exchangers with dedicated fans. These units reclaim energy from exhaust air and transfer it back into incoming fresh air, enhancing overall efficiency without sacrificing comfort or indoor air quality. Each type plays a crucial role in optimizing thermal management across diverse environments.

Heat Exchange Ventilation Fans: Revolutionizing Energy-Efficient Cooling

Heat exchangers are essential components in systems designed to transfer heat efficiently. In industrial and residential applications, they play a critical role in maintaining optimal temperatures and reducing energy consumption. Using the principles of thermodynamics, heat exchangers facilitate the transfer of heat from one medium to another, helping regulate temperature without additional energy inputs. This technology is central to achieving both cost-effective and environmentally friendly solutions.

A significant advancement in heat-exchange systems is introducing the heat exchange ventilation fan. These fans enhance heat transfer by facilitating air movement across heat exchanger surfaces, thereby improving heat absorption and dissipation. By circulating air efficiently, these fans ensure that heat is transferred at the right rate, maintaining comfortable conditions while reducing the need for mechanical cooling systems. As a result, energy consumption is minimized, and system performance is optimized.

The growing demand for energy-efficient solutions has made heat-exchange systems indispensable in various industries. Whether in commercial, industrial, or residential settings, they are an excellent way to control temperature. With advancements in fan technology and the integration of smart systems, the potential for even greater energy savings and environmental benefits continues to grow. This makes heat-exchange systems a cornerstone of sustainable design and energy management.

Factors to Consider When Choosing a Heat Exchanger-Fans

When selecting a heat exchanger-fans , several factors come into play. First, consider the required airflow rate. This metric will dictate how effectively the fan can move air through the system. Next is the fan’s efficiency rating. High-efficiency models not only save energy but also reduce operational costs over time. Noise levels are another crucial aspect; quieter fans create a more comfortable working environment.

Durability matters, too. Look for materials that withstand high temperatures and corrosive environments to ensure longevity. Don’t forget about size and compatibility with your existing system—an ill-fitting unit can lead to inefficiencies or increased wear and tear. Evaluate maintenance requirements. Some fans offer easier service access than others, saving time and effort in upkeep tasks.

Impact of Heat Exchanger-Fans S on Energy Consumption

Heat exchanger-fans s play a crucial role in regulating energy consumption within industrial processes. These fans help maintain optimal temperatures with minimal energy loss by facilitating efficient heat transfer. When used correctly, they can significantly reduce the need for extra heating or cooling systems, leading to lower operational costs and decreased reliance on fossil fuels. Moreover, high-quality heat exchanger-fans s are designed to operate at peak efficiency. They consume less power while delivering superior airflow performance, meaning fewer resources are wasted during operation.

Investing in advanced fan technology can result in long-term savings for businesses. Enhanced efficiency translates into reduced carbon footprints and promotes sustainability efforts across various industries. By optimizing temperature control through effective fan usage, companies not only save money but also contribute positively to environmental conservation initiatives.

How Heat Exchange Systems Improve Indoor Air Quality with Fans

Heat-exchange systems are crucial in improving indoor air quality by regulating air circulation and promoting proper ventilation. By using fans, these systems help distribute fresh air throughout indoor spaces while expelling stale air, creating a balanced and healthier environment. The continuous movement of air reduces humidity, odours, and pollutants, contributing to an overall better living or working atmosphere.

In a heat-exchange system, the fan is integral to its operation, as it ensures that air is constantly moving, passing through filters and heat exchangers. These components capture and remove harmful particles, allergens, and volatile organic compounds (VOCs) from the air, thus improving air quality. The system’s ability to efficiently exchange heat while ventilating the space keeps it fresh and comfortable. This is particularly beneficial in tightly sealed buildings where traditional ventilation might be insufficient.

By incorporating heat-exchange systems with fans, buildings can enjoy reduced energy consumption while maintaining high indoor air quality. These systems provide a sustainable solution for managing temperature and airflow, reducing the need for constant mechanical cooling or heating. With their ability to balance energy efficiency and air quality, heat exchange systemsare ideal for residential and commercial spaces looking to improve comfort and health.

Maintenance and Troubleshooting Tips for Optimal Performance

Heat exchanger-fans s are critical for enhancing the efficiency of heat transfer systems. Regular upkeep is essential to maintain their optimal performance.

Routine Cleaning and Inspection

Keep the fan blades, filters, and surrounding areas clean from debris and dust. Regular inspections help identify potential issues early.

Lubrication of Moving Parts

Ensure all moving parts are properly lubricated to reduce friction and prevent wear. Over time, this helps maintain the fan’s efficiency.

Check Fan Motor Functionality

Periodically test the fan motor to ensure it operates smoothly. Any abnormal sounds or vibrations could indicate potential mechanical problems.

Examine Electrical Connections

Loose or damaged electrical connections can lead to poor fan performance. Check all wiring and connections to prevent electrical failures.

Monitor Fan Speed and Pressure

Keep track of fan speed and pressure levels to ensure the system is running within the recommended parameters. Adjust if necessary.

Address Vibration Issues Promptly

Excessive vibration can lead to fan damage and inefficiency. Ensure that the fan is properly mounted and balanced to avoid this issue.

Regular maintenance and early troubleshooting are crucial for extending the lifespan and efficiency of heat exchanger-fans s.

How Heat Exchanger-Fans S Reduce Thermal Resistance

Heat exchanger-fans s play a crucial role in minimizing thermal resistance. By increasing airflow across the heat exchange surface, they enhance the transfer of heat between fluids. When air moves rapidly over hot surfaces, it helps absorb excess heat. This process reduces temperature gradients and ensures more efficient energy transfer. Cooler air absorbs heat from warmer areas more effectively when fans assist. Moreover, these fans can maintain optimal temperatures within systems, preventing overheating. When components operate at ideal conditions, overall efficiency improves dramatically.

The design and placement of these fans are also vital. A well-positioned fan can create a uniform flow pattern that maximizes contact with heated surfaces while reducing pockets of stagnant air that contribute to thermal resistance. This attention to detail leads to better performance in industrial processes where precise temperature control is essential for productivity and safety.

Understanding Heat Exchanger-Fans Noise and How to Minimize It

Heat exchanger-fans noise can be a nuisance in various industrial settings. Understanding its origins is essential for effective mitigation. Typically, noise arises from the vibration of components or turbulent airflow around blades. Regular maintenance is key to minimizing this issue. Ensure that fans are properly aligned and securely mounted to reduce vibrations. Using rubber mounts or isolators can significantly dampen sound transmission.

Blade design plays a critical role as well. Fans with specially engineered blades create smoother airflow, less turbulence and reduced noise levels. Another effective strategy involves installing acoustic panels or barriers near noisy equipment. These materials absorb sound waves and prevent them from spreading throughout the space. Consider variable speed drives that allow fans to operate at lower speeds during off-peak times, further decreasing noise without sacrificing efficiency while promoting comfort in workspaces.

The Role of Blade Design in Heat Exchanger-Fans Efficiency

Blade design plays a pivotal role in the efficiency of heat exchanger-fans s. The shape and angle of each blade directly impact airflow dynamics, which is crucial for effective heat transfer. Aerodynamic blades can minimize turbulence while maximizing air movement, leading to better performance without consuming excessive energy. Materials also matter; lightweight yet durable options enhance longevity and reduce wear.

Design considerations such as blade pitch and curvature allow customization for specific applications, whether cooling or heating. Moreover, advanced computational fluid dynamics tools enable engineers to optimize designs before production. This ensures that every fan achieves peak efficiency right from the start. Innovative blade design translates into improved operational reliability and reduced maintenance needs, enhancing overall system performance.

Conclusion

Heat exchanger fans play a crucial role in enhancing the efficiency of heat transfer systems. They ensure that heat exchangers operate optimally by promoting consistent airflow and reducing the risk of overheating. Whether in industrial, commercial, or residential applications, these fans help maintain a steady temperature, improving energy efficiency and extending the lifespan of equipment. Proper maintenance of heat exchanger-fans s can prevent system failures and reduce operational costs. Understanding their function and choosing the right fan for your heat exchanger can significantly affect overall system performance.

FAQ’s

What is the role of a heat exchanger fan?

Heat exchanger fans circulate air or fluid over the heat exchange surfaces, ensuring efficient heat transfer. They help maintain consistent temperature control, allowing the system to work optimally. By promoting effective airflow, they prevent overheating and improve overall energy efficiency.

How do heat exchanger-fans s improve energy efficiency?

Fans reduce the workload on the entire system by ensuring that heat exchangers are consistently cooled or heated. Less energy is consumed to achieve the desired temperature, improving energy savings and reducing operational costs.

What types of heat exchanger-fans s are there?

There are two main heat exchanger-fans s: axial fans, which move air parallel to the shaft, and centrifugal fans, which move air at a right angle to the shaft. The fan choice depends on the system requirements, such as airflow, pressure, and space constraints.

How often should I maintain my heat exchanger-fans ?

Regular maintenance is crucial for ensuring efficient operation. It’s recommended that the fan be inspected at least twice a year to check for dust, debris, and wear on the blades or motor. Cleaning and lubricating the components can prevent premature failure and extend the fan’s lifespan.

Can a malfunctioning heat exchanger-fans affect the system?

Yes, a malfunctioning fan can lead to poor heat transfer, causing the system to overheat. If not addressed promptly, this can result in energy inefficiency, increased wear and tear on components, and even complete system failure.

| Related Business Listings |

| Contact Directory |

| Local Business Profiles |