In an era where precision and speed are crucial for success in manufacturing and product customization, laser engraving has become a game-changer for businesses across various industries. Lumitool, a leader in advanced laser technology, provides cutting-edge laser engravers that offer exceptional performance, versatility, and durability. In this post, we will explore how Lumitool laser engraver are transforming industries by delivering unparalleled results with unmatched precision, speed, and efficiency.

What is Laser Engraving?

Laser engraving is a non-contact process where a focused laser beam is used to etch or engrave a design, text, or logo into the surface of a material. Unlike traditional engraving methods that involve physical tools or chemicals, laser engraving uses highly concentrated light energy to vaporize the surface of the material, leaving behind a permanent mark. This process ensures high precision, intricate detailing, and deep, permanent engravings that won’t fade over time.

Laser engraving is popular in industries requiring high-quality and precise marking, such as automotive, aerospace, electronics, medical devices, and consumer goods. This technology has revolutionized the way businesses approach engraving, allowing them to achieve better results while reducing operational costs and time.

Why Choose Lumitool Laser Engravers?

Lumitool offers a wide range of laser engravers that cater to the needs of modern industries. Here are some key reasons why Lumitool laser engravers are the top choice for businesses seeking precision, efficiency, and innovation:

- Unrivaled Precision

Lumitool laser engravers are known for their exceptional precision and accuracy. With advanced technology and fine-tuned laser beams, these systems can engrave detailed designs with the utmost clarity. Whether it’s for engraving small, intricate text or creating complex patterns, Lumitool engravers deliver results that meet the highest standards of quality. - Versatility in Materials

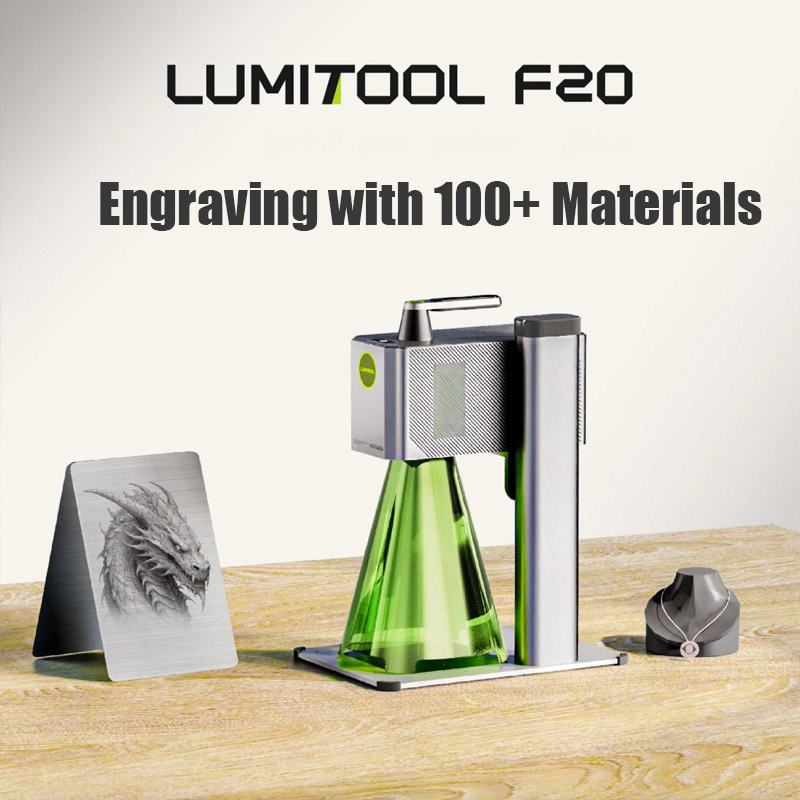

Lumitool laser engravers are incredibly versatile and can work with a wide range of materials, from metals such as stainless steel and aluminum to plastics, wood, leather, glass, and more. This adaptability makes Lumitool systems ideal for industries with diverse material requirements. Manufacturers and artisans alike can rely on these machines to engrave a wide variety of substrates with precision. - High-Speed Engraving

Speed is crucial in today’s fast-paced manufacturing environment. Lumitool laser engravers are designed for high-speed operations, allowing businesses to increase throughput and reduce turnaround times. Whether engraving small batches or large volumes of products, Lumitool machines can achieve rapid processing speeds without compromising the quality of the engraving. This makes them a valuable asset for businesses aiming to meet high production demands. - Low Maintenance and High Durability

Lumitool’s laser engravers are engineered for durability and long-lasting performance. These machines require minimal maintenance, which translates to lower downtime and reduced operational costs. Their rugged design ensures that they can withstand demanding industrial environments, making them a reliable choice for high-volume production. The low maintenance requirements also help businesses save on service costs, making them an economical investment. - User-Friendly Interface

Lumitool laser engravers come with intuitive software interfaces that make them easy to operate, even for those who are new to laser engraving. The machines are equipped with advanced control features that allow for precise adjustments and customization of engraving settings. Additionally, the software is designed for ease of use, providing users with a seamless experience from start to finish. - Customization and Branding

Laser engraving offers businesses a unique opportunity to customize their products and enhance their branding. Lumitool laser engravers can be used to create personalized engravings on items such as jewelry, trophies, promotional products, and even electronics. By engraving logos, names, or custom designs, businesses can differentiate their products in the marketplace and create a strong brand identity.

Applications of Lumitool Laser Engraving Technology

Lumitool laser engravers are used across various industries due to their precision, versatility, and speed. Some of the most common applications include:

- Automotive Industry

In the automotive sector, laser engraving is used to mark components with essential information such as serial numbers, part numbers, logos, and identification codes. This ensures that parts can be traced for quality control, regulatory compliance, and maintenance. Lumitool laser engravers can handle a wide range of materials used in the automotive industry, including metals and plastics, making them ideal for marking both exterior and interior components. - Electronics and Semiconductors

Laser engraving is widely used in the electronics and semiconductor industries to mark circuit boards, microchips, and other delicate components. Lumitool laser engravers can produce precise, high-resolution markings on small-scale electronic parts, helping businesses maintain traceability and product integrity. This is crucial for product identification, testing, and warranty purposes. - Medical Device Manufacturing

In the medical industry, precision is critical. Lumitool laser engravers are used to mark medical devices and surgical instruments with important information such as serial numbers, expiration dates, and regulatory codes. The non-contact nature of laser engraving ensures that medical devices remain undamaged during the marking process, while the permanent nature of the engravings ensures compliance with industry regulations. - Jewelry and Luxury Goods

Lumitool’s laser engravers are widely used in the jewelry and luxury goods industries for engraving intricate designs, logos, and personalized messages onto various materials such as metals, gemstones, and leather. These engravers allow jewelers to produce fine, detailed engravings that enhance the value and appeal of their products. Personalized engravings are also popular in the creation of bespoke pieces for customers. - Aerospace and Defense

Laser engraving is essential in the aerospace and defense sectors, where precision and traceability are paramount. Lumitool laser engravers are used to mark parts with serial numbers, safety information, and compliance codes, ensuring that each component is easily identifiable throughout its lifecycle. This helps manufacturers maintain quality control and meet regulatory requirements in highly regulated industries. - Consumer Goods and Packaging

In the consumer goods sector, laser engraving is used for product customization, branding, and packaging. Lumitool laser engravers can create detailed marks on packaging materials like plastic, cardboard, and glass. They are also used to engrave logos and product information on consumer items such as electronics, personal accessories, and promotional products.

The Future of Laser Engraving with Lumitool

As industries continue to evolve and demand higher precision, efficiency, and sustainability, Lumitool remains at the forefront of laser engraving technology. Their commitment to innovation and customer satisfaction ensures that businesses can rely on their products for years to come. Lumitool continues to enhance its laser engravers, incorporating the latest technological advancements to meet the needs of modern manufacturing.

Conclusion

Lumitool laser engravers provide businesses with a reliable, efficient, and cost-effective solution for achieving high-quality, permanent markings on a wide variety of materials. Whether you’re looking to improve product branding, ensure traceability, or enhance manufacturing processes, Lumitool’s laser engravers are designed to meet your needs. With advanced features, durability, and precision, Lumitool offers the ultimate solution for industrial engraving needs.