Shotcrete has become a cornerstone of both civil engineering and mining operations, thanks to its versatility, durability, and efficiency. From tunnel linings construction to underground concrete support, shotcrete plays a crucial role in reinforcing infrastructure. One prominent provider of specialized shotcrete equipment and solutions is Minecrete South Africa, which caters to the demands of both civil and mining projects.

In this blog, we’ll explore how civil engineering shotcrete is applied across various projects and the importance of Minecrete solutions in meeting the needs of South Africa’s mining industry.

The Role of Shotcrete in Civil Engineering Projects

In civil engineering, shotcrete is extensively used to stabilize tunnels, bridges, retaining walls, and slopes. Its unique properties make it ideal for environments that require both strength and flexibility.

Some common applications include:

- Tunnel Linings: Shotcrete provides fire resistance and structural integrity, ensuring safer underground passages.

- Slope Stabilization: Civil engineering shotcrete is applied on embankments and cliffs to prevent landslides and erosion.

- Retaining Walls: In urban construction, shotcrete is used to build retaining walls that protect infrastructure from soil shifts.

Minecrete South Africa: Leading Mining Shotcrete Solutions

Minecrete South Africa specializes in providing advanced shotcrete equipment and materials to the mining industry. Their solutions are tailored for underground environments, ensuring safe and stable operations in the most demanding conditions.

What Makes Minecrete Solutions Essential?

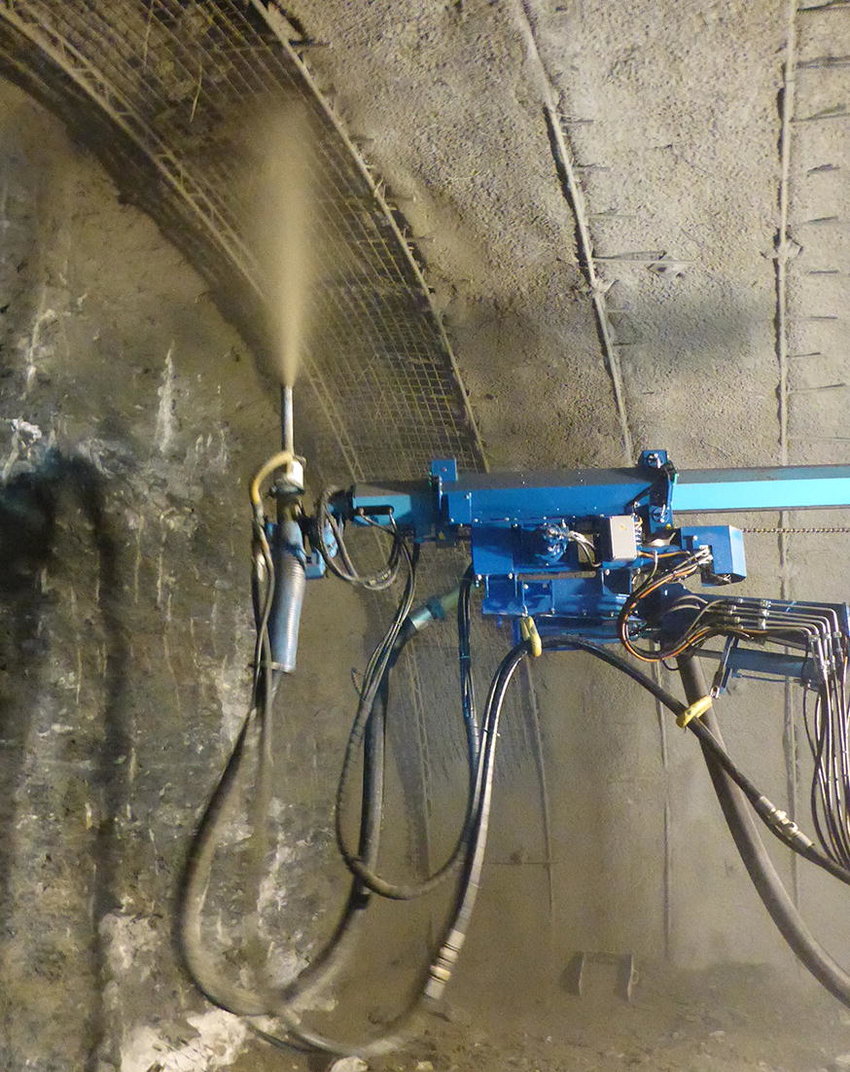

- Mincreter Machine: Minecrete South Africa offers state-of-the-art shotcrete machinery like the Mincreter, designed to efficiently apply shotcrete in confined mining spaces.

- Customized Shotcrete Mixes: Minecrete develops high-performance shotcrete mixes that meet the specific needs of each project, ensuring optimal adhesion and durability.

- Support for Deep-Level Mining: Their solutions help stabilize underground chambers and shafts, minimizing the risk of rockfalls in deep mining environments.

How Civil Engineering Shotcrete and Minecrete Solutions Ensure Safety

- Immediate Ground Support

In both civil engineering projects and mining tunnels, shotcrete offers instant stabilization upon application, preventing collapse during excavation. Minecrete’s advanced equipment ensures accurate, fast application even in confined spaces. - Fire Resistance in Tunnels

Civil engineering shotcrete is essential for road and rail tunnels, providing an additional layer of fire protection. Similarly, in mining, shotcrete minimizes the risk of fire spreading underground. - Waterproofing and Crack Prevention

Underground projects are prone to water infiltration, which can weaken the structure. Shotcrete acts as a waterproof barrier, reducing the chance of leaks and cracks. Minecrete’s high-quality mixes ensure long-term durability in these challenging environments. - Adaptability in Confined Spaces

Minecrete equipment, such as the Mincreter, is designed for use in narrow mine shafts and tunnels, ensuring efficient concrete application where space is limited. This flexibility also benefits civil engineering projects, especially those with complex geometries.

Applications of Shotcrete in South Africa

- Mining Tunnels and Shafts: Shotcrete is crucial for stabilizing underground passages in South African mines. Minecrete South Africa offers solutions that ensure efficient support in deep-level operations.

- Transportation Infrastructure: Civil engineering shotcrete plays a pivotal role in road and rail tunnels, ensuring they remain stable, waterproof, and fire-resistant.

- Slope Stabilization and Retaining Walls: In both urban and rural construction, shotcrete is used to reinforce slopes and protect infrastructure from erosion.

- Hydropower Projects: Shotcrete helps reinforce water tunnels and channels, preventing leakage and structural degradation.

The Advantages of Professional Shotcrete Solutions

Working with experienced shotcrete providers ensures your project benefits from the latest advancements in technology and materials. Key advantages include:

- Compliance with South African Safety Standards: Professional shotcrete contractors follow all relevant regulations for civil and mining projects.

- Access to Advanced Equipment: Providers like Minecrete South Africa offer automated spraying systems, ensuring faster and more precise application.

- Tailored Solutions for Mining and Infrastructure Projects: Both civil engineering and mining projects benefit from customized shotcrete mixes designed for their unique challenges.

Conclusion

Whether for civil engineering infrastructure or mining tunnels, shotcrete remains a critical tool for stabilization, waterproofing, and fire protection. Minecrete South Africa offers specialized solutions that meet the challenges of underground construction, ensuring both safety and long-term durability.

By leveraging civil engineering shotcrete and Minecrete solutions, South African projects can ensure their tunnels, walls, and slopes are built to withstand the test of time. Whether working on a mine shaft or transportation tunnel, investing in the right shotcrete solution is key to building infrastructure that lasts.