In the fast-paced world of industrial manufacturing, precision, efficiency, and reliability are paramount. With ever-increasing demands for faster production times and high-quality products, industries across the globe are turning to industrial engravers to meet these challenges. An industrial engraver, particularly a laser engraver, offers unmatched advantages in terms of speed, quality, and versatility. Whether you’re marking metals, plastics, or other materials, an industrial engraver can transform your production processes, resulting in higher quality products and reduced operational costs. In this article, we will explore the key features and benefits of the Lumitool Industrial Laser Engraver, a cutting-edge solution designed to meet the needs of modern businesses.

What is an Industrial Engraver? An industrial engraver, also known as an industrial laser engraver, is a machine designed to engrave or mark materials with high precision using a laser beam. The laser’s intense energy vaporizes a thin layer of the material’s surface, leaving behind a permanent mark. Unlike traditional engraving methods, such as rotary or hand engraving, laser engraving is a non-contact process that ensures the materials remain intact, and the marks are clean, sharp, and precise.

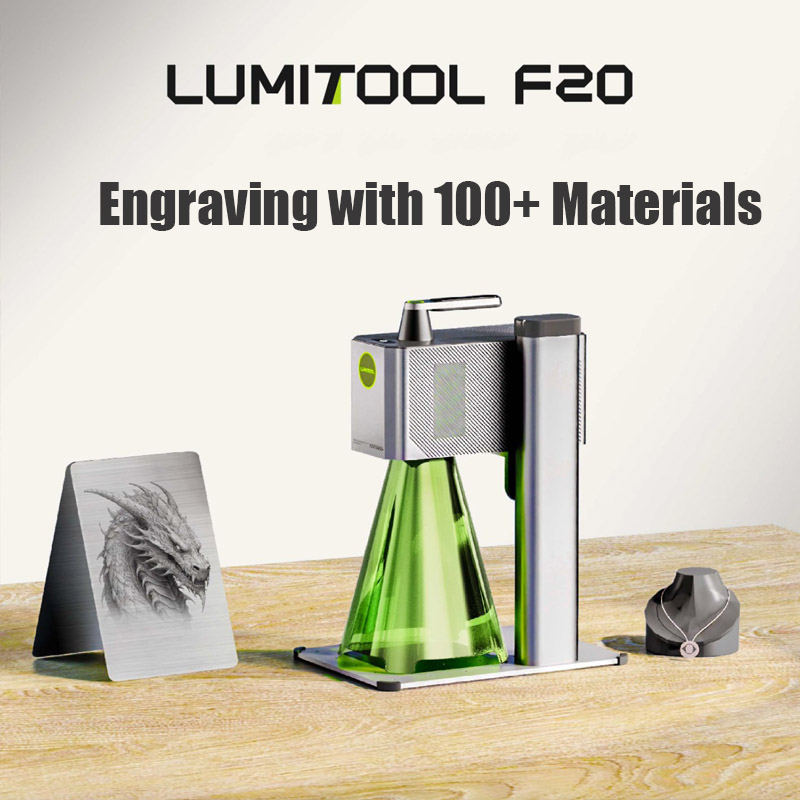

The Lumitool Industrial Laser Engraver is a powerful and efficient tool that provides businesses with the ability to mark and engrave various materials, including metals, plastics, ceramics, rubber, glass, and more. It’s a versatile solution for industries such as automotive, aerospace, electronics, medical devices, and consumer goods, providing high-quality results in record time.

Why Should You Choose an Industrial Laser Engraver for Your Business? Investing in an industrial laser engraver is a smart move for businesses that require precision, durability, and cost-effective solutions for product marking and engraving. Here are the key reasons why you should consider incorporating an industrial engraver into your operations:

- Precision and Accuracy: One of the primary benefits of industrial laser engravers is their precision. Laser beams can be focused to a very fine point, allowing for incredibly detailed markings and engraving. Whether you need to engrave logos, serial numbers, barcodes, or intricate designs, an industrial engraver will produce clear, crisp results every time. This level of accuracy is essential for industries that rely on traceability, such as automotive, aerospace, and electronics.

The Lumitool Industrial Laser Engraver offers exceptional precision, ensuring that every mark is accurately placed, even on small or delicate components. This helps businesses meet industry standards and customer expectations for quality.

- Speed and Efficiency: In the manufacturing world, time is money, and businesses must keep up with high production demands. Traditional engraving methods can be slow and labor-intensive, which is why laser engraving is a game-changer. Industrial laser engravers are capable of marking materials at high speeds without compromising quality, allowing businesses to complete large volumes of work in a shorter amount of time. This leads to increased productivity and faster turnaround times.

The Lumitool Industrial Laser Engraver is designed for rapid engraving, reducing downtime and helping businesses stay competitive. Whether you’re engraving single items or running continuous production, this machine can keep pace with your business’s needs.

- Durability of Marks: Another significant advantage of laser engraving is the durability of the markings. Laser engraving creates permanent marks that are resistant to fading, scratching, or wearing away, making them ideal for industrial applications. In industries like automotive and electronics, where traceability and product identification are crucial, having markings that last is essential.

With the Lumitool Industrial Laser Engraver, you can ensure that your marks remain legible and intact throughout the lifespan of the product, even in harsh environments or extreme conditions.

- Versatility Across Materials: Industrial laser engravers are highly versatile and can mark or engrave a wide range of materials. This includes metals such as stainless steel, aluminum, and titanium, as well as non-metals like plastics, rubber, wood, ceramics, and glass. This adaptability makes laser engraving an excellent solution for a variety of industries and applications.

The Lumitool Industrial Laser Engraver excels in versatility, handling different materials with ease and providing high-quality results regardless of the substrate. Whether you’re marking delicate components or durable industrial parts, this engraver is up to the task.

- Non-contact Process: Unlike traditional engraving techniques that may involve physical contact with the material (which could cause damage), laser engraving is a non-contact process. This means that the laser doesn’t physically touch the material, eliminating the risk of deformation, warping, or other mechanical damage. This is especially beneficial for sensitive or fragile materials, such as thin metal sheets or delicate plastic components.

By using a non-contact engraving method, the Lumitool Industrial Laser Engraver ensures that your materials stay intact, reducing the risk of errors and damage during production.

- Reduced Operating Costs: While the initial investment in an industrial laser engraver may seem high, the long-term savings are significant. Laser engraving machines are known for their efficiency and durability, requiring less maintenance than traditional engraving methods. With fewer moving parts and a longer lifespan, laser engravers offer lower operational costs over time.

The Lumitool Industrial Laser Engraver offers a high return on investment by reducing labor costs and increasing production efficiency. Additionally, the machine’s energy-efficient design helps businesses lower their energy bills, further enhancing its cost-effectiveness.

- Customization and Personalization: In today’s competitive market, many businesses are looking to offer customized or personalized products to stand out from the crowd. Laser engraving provides a precise and cost-effective way to add custom text, logos, or designs to products. Whether you’re personalizing gifts, creating unique promotional items, or marking products with serial numbers or brand logos, an industrial engraver gives you the flexibility to meet these needs.

The Lumitool Industrial Laser Engraver can handle complex customization tasks with ease, allowing businesses to offer personalized products and meet customer demands for unique designs.

Applications of Industrial Engraving: The versatility of industrial engravers makes them suitable for a wide range of applications across various industries. Some common uses include:

- Product Marking and Identification: Laser engraving is often used for marking serial numbers, barcodes, QR codes, and logos on products. This ensures traceability, helps with inventory management, and meets industry regulations.

- Component and Part Engraving: Industries like automotive and aerospace use laser engraving to mark metal parts, components, and assemblies. These marks are crucial for identifying parts, ensuring quality control, and meeting regulatory requirements.

- Personalized Products: Laser engraving is also used in consumer goods, where businesses offer customized products such as engraved gifts, jewelry, and promotional items.

- Medical Device Marking: In the medical industry, laser engraving is used to mark medical devices with critical information like expiration dates, serial numbers, and certification marks. The precision and durability of the marks ensure that they remain legible throughout the device’s lifespan.

Conclusion: An industrial engraver is a must-have tool for businesses that demand high precision, speed, and durability in their marking and engraving processes. Whether you’re marking automotive parts, personalizing products, or adding important information to medical devices, a laser engraver provides an efficient and cost-effective solution. The Lumitool Industrial Laser Engraver stands out as a reliable and versatile option, offering businesses the ability to achieve high-quality results while reducing operational costs.