In the competitive world of business, efficiency and quality are paramount. Vacuum food sealers offer a versatile solution to many industrial needs, providing various benefits across different sectors. Whether you are in the food industry, electronics, or even art preservation, a vacuum bag sealer machine can enhance your operations in ways you might not have considered. In this blog post, we will explore 12 industrial applications of vacuum machines and how they can benefit your business.

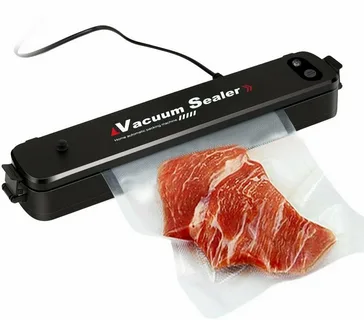

Extending Shelf Life of Food Products

A vacuum bag sealing machine plays a crucial role in prolonging the shelf life of food products by creating an airtight environment that prevents spoilage and freezer burn. By eliminating air, the growth of bacteria and mould is inhibited, keeping food fresher for extended periods. This is particularly advantageous for businesses in the food sector, as it helps maintain the quality and taste of their products. Additionally, extending shelf life reduces the frequency of restocking, thus saving both time and resources.

Packaging Ready Meals

With the growing demand for convenience foods, vacuum sealing machines have become indispensable in packaging ready meals. By vacuum sealing these meals, companies can ensure their products remain fresh from packaging until they reach the consumer’s kitchen. This method keeps the food delicious and safe and allows for efficient storage and transportation. Vacuum sealing helps maintain the quality and taste of ready meals, making it easier for consumers to enjoy high-quality, convenient food options. Additionally, it enables businesses to streamline their packaging processes, saving time and reducing costs.

Pharmaceutical Applications

Vacuum bag sealers are crucial in the pharmaceutical industry to maintain the integrity of medications and medical supplies. These machines create a sterile, airtight environment that prevents contamination and degradation, ensuring that products remain safe and effective for consumers. Vacuum sealing is particularly beneficial for sensitive items such as injectable medications, diagnostic kits, and surgical instruments, requiring strict conditions to maintain efficacy.

Additionally, vacuum-sealed packaging can help extend pharmaceutical products’ shelf life, reduce waste, and improve inventory management. This level of protection is essential for meeting regulatory standards and providing high-quality, reliable products to the market.

Protecting Electronic Components

Electronic components are susceptible to environmental factors such as moisture and dust. Vacuum sealing provides a protective barrier that shields these components from potential damage during storage and transport. By creating an airtight environment, vacuum food sealers help maintain electronic parts’ integrity and functionality. This protection is crucial for components like circuit boards, semiconductors, and other delicate hardware that could otherwise suffer from corrosion or contamination. Reducing the risk of product failure enhances customer satisfaction and helps lower costs associated with returns and repairs.

Preserving Laboratory Samples with Food Vacuum Sealer

Laboratories require precise conditions to preserve the integrity of samples. Food Vacuum Sealer is highly effective in this setting, providing an airtight seal that prevents contamination and degradation. This method benefits biological samples, chemical reagents, and other sensitive materials that must be stored or transported under controlled conditions. Vacuum sealing ensures that the samples remain unaltered by environmental factors such as moisture, air, or microbial contamination. By maintaining sample quality, laboratories can provide more reliable and accurate experimental results, enhancing the validity of their research and diagnostics.

Safeguarding Important Documents

Businesses often handle essential documents that require long-term preservation. Vacuum food sealers provide a secure solution by creating an airtight barrier that protects against moisture, dust, and pests. This method is particularly effective for archiving contracts, certificates, legal papers, and other critical documents.

By vacuum sealing, companies can ensure these papers remain legible and intact over time. This level of protection is indispensable for industries where document integrity is paramount, such as legal firms, financial institutions, and corporate offices. The process is also straightforward, making it a practical option for businesses looking to enhance their document management systems.

Packaging Industrial Parts

Vacuum sealing plays a crucial role in the manufacturing industry, especially for the storage and protection of industrial parts. By removing air and sealing components in airtight packaging, vacuum food sealers create a protective barrier against rust, corrosion, and moisture-related damage. This ensures that sensitive parts, such as gears, bearings, and mechanical components, remain in excellent condition during transport and storage, preserving their functionality and longevity.

Enhanced Protection for Critical Components

Exposure to air and moisture can lead to gradual degradation of metal parts, impacting their reliability and performance. Vacuum sealing eliminates this risk by isolating components from environmental factors. This method is particularly valuable for manufacturers dealing with large inventories, as it minimizes the need for constant maintenance or replacement due to premature wear and tear. Parts arrive at their destination in pristine condition, ready for immediate use without additional treatment or cleaning.

Improved Inventory Management

In addition to protection, vacuum sealing supports more efficient inventory management. The sealed packages allow for clear labelling and stacking, making it easy to identify parts and organize them based on size, usage, or production stage. With streamlined storage, manufacturing facilities can access necessary components quickly, reducing downtime and keeping production schedules on track.

Overall, vacuum sealing enhances the quality and reliability of industrial parts, ensuring smoother production processes and higher customer satisfaction. This packaging solution not only safeguards components but also contributes to operational efficiency, a win-win for manufacturers and clients alike.

Ensuring Freshness of Coffee and Tea using a Vacuum Sealer Machine

Coffee and tea are highly susceptible to air, moisture, and light exposure degradation. Vacuum Sealer Machine offers an effective solution by creating an airtight seal that locks in the aroma and flavour of these delicate products. This method benefits businesses producing, packaging, and retailing coffee and tea. By maintaining the freshness of these products, companies can deliver a consistently high-quality experience to their customers.

Additionally, vacuum sealing allows extended storage periods without compromising the taste and quality, reducing waste and ensuring stock remains sellable for extended durations. This level of preservation is crucial for maintaining brand reputation and customer satisfaction in the competitive beverage market.

Packaging for Sous Vide Cooking

Vacuum bag sealers are indispensable in sous vide cooking, providing an airtight environment for this precise culinary technique. By vacuum sealing ingredients, chefs can ensure they are even cooking and retain the food’s natural flavours and nutrients. This method also allows for enhanced marination, as the vacuum process helps infuse flavours more deeply into the food. Businesses in the hospitality sector can greatly benefit from offering sous vide options, as this technique yields consistently high-quality dishes that appeal to discerning customers.

Additionally, vacuum-sealed sous vide packages simplify storage and inventory management, as they can be easily labelled and stacked, saving valuable kitchen space. This efficiency is particularly beneficial for busy commercial kitchens looking to optimise their operations and deliver top-notch dining experiences.

Preserving Art and Antiques with Vacuum Sealers

Art and antiques are invaluable and often irreplaceable, necessitating meticulous care for their preservation. Vacuum Sealers provide an effective solution by creating an airtight seal that protects these treasures from environmental damage. Humidity, dust, and air pollutants can significantly degrade art and antiques. Vacuum sealing shields These items from such detrimental effects, ensuring their longevity and value. This method benefits museums, galleries, and private collectors who require reliable preservation techniques. Additionally, vacuum sealing can prevent oxidation and mould growth, which are common threats to delicate materials like paper, fabric, and metal.

Reducing Waste in Food Production

Vacuum food sealers are pivotal in reducing waste within the food production industry. By creating an airtight seal, these machines prevent spoilage and extend the freshness of both raw ingredients and finished products. This process minimises the likelihood of products being discarded due to spoilage or contamination, resulting in significant cost savings for businesses.

Additionally, vacuum sealing allows for more accurate portion control and inventory management, helping companies to utilise resources more efficiently. This method also supports the storage of bulk quantities without compromising quality, enabling producers to take advantage of bulk purchasing discounts.

By maintaining the integrity of food products for extended periods, vacuum food sealers contribute to a more sustainable production process, reducing the environmental impact associated with food waste. The ability to vacuum seal and store seasonal products for extended periods further optimises resource utilisation, ensuring that high-quality ingredients are available year-round.

Enhancing Logistics and Supply Chain Management

Using vacuum sealing machines can significantly improve logistics and supply chain management for businesses across various industries. By vacuum sealing products, enterprises ensure that items remain protected from environmental factors such as moisture, dust, and air, which can compromise quality during transit. This level of protection is particularly beneficial for perishable goods, sensitive electronics, and delicate components, reducing the likelihood of damage or spoilage.

Furthermore, vacuum sealing allows for more compact and efficient packaging, optimising space utilisation in storage and transportation. This leads to cost savings on shipping and warehousing, as more products can be transported or stored in the same space. Additionally, vacuum-sealed packages are more accessible to label and organise, streamlining inventory management and reducing the time required for handling and sorting goods. This efficiency can lead to faster turnaround times and improved customer satisfaction.

By maintaining the integrity and quality of products throughout the supply chain, businesses can reduce the costs associated with returns, replacements, and wastage. Overall, incorporating vacuum sealing machines into logistics and supply chain operations enhances product protection and contributes to more efficient and cost-effective business processes.

Conclusion

Incorporating a vacuum bag sealer machine into your business operations can lead to significant advantages across various industries. From extending the shelf life of food products to enhancing logistics and supply chain management, these machines provide versatile solutions that improve efficiency and reduce waste. Whether you are packaging ready meals, safeguarding sensitive items, or preserving invaluable artifacts, vacuum food sealers help maintain quality and integrity. By investing in this technology, businesses can enhance customer satisfaction, streamline processes, and ultimately drive profitability. Embracing vacuum sealing is not just a trend; it’s a strategic move towards a more efficient future.

Frequently Asked Questions (FAQs)

1. What types of businesses can benefit from using Vacuum Bag Sealer Machine?

Vacuum Bag Sealer Machine can benefit a variety of industries, including food production, pharmaceuticals, electronics, laboratories, hospitality, and art preservation. Any business that requires efficient packaging, protection from environmental factors, or extended shelf life for products can gain advantages from vacuum sealing.

2. How does vacuum sealing extend the shelf life of food products?

Vacuum sealing removes air from the packaging, which helps inhibit the growth of bacteria and mold, preventing spoilage. By creating an airtight seal, it protects food from oxidation and freezer burn, allowing it to remain fresh for longer periods.

3. Are vacuum sealer machines easy to use?

Yes, most vacuum sealer machines are designed for user-friendly operation. They often feature simple controls and automatic sealing functions, making them accessible for staff training and integration into existing workflows.

4. Can vacuum sealing help reduce food waste?

Absolutely! By extending the shelf life of food products and preventing spoilage, vacuum sealing helps businesses reduce food waste significantly. This leads to cost savings and supports more sustainable practices in food production.

5. Is vacuum sealing effective for non-food items, such as documents and electronics?

Yes, vacuum sealing is highly effective for non-food items as well. It protects documents from moisture, dust, and pests, and shields electronic components from environmental damage. This versatility makes vacuum sealers valuable across various applications beyond food preservation.

| Related Business Listings |

| Contact Directory |

| Local Business Profiles |